The Need to Protect Agricultural Land by Minimizing Compaction Caused by Machinery. The necessity of protecting agricultural land by minimizing soil compaction caused by machinery and equipment has led to both an increase in tire sizes and the development of tires designed to operate at low pressures, even below one bar. In both cases, the ultimate goal is to maximize the contact area of the tread to ensure lower specific pressures for a given load. The underlying idea is sound, but to make it a reality, these specially designed wheels must be as easy to assemble and as stable in use as traditional wheels.

“Wide” tires and those operating at low pressures must therefore fit onto their respective rims without causing issues different from those posed by traditional tires. Moreover, once mounted, they must resist de-beading or slipping under high torque conditions. Titan, one of the world’s leading manufacturers of rims, tires, and complete wheel assemblies, realized early on that installing large or low-pressure tires on rims was not as straightforward as it might seem. Large tires with particularly rigid sidewalls often struggled to seat correctly on the rim, leading to frequent bead breakage and fitting issues.

This caused bouncing effects when such wheels were used on agricultural machinery capable of high speeds on the road and operational malfunctions in the field under high torque conditions.

Available This Year

This prompted Titan to redesign its rims, developing a geometry to prevent these potential failures. The new profile was unveiled last November in Germany and has been officially available on the market since September this year. Called the “Lw,” the new design represents a breakthrough in its field. In addition to offering the same structural performance as current profiles on the market, it also provides a series of operational advantages that positively impact tire mounting. It ensures the tire bead sits correctly against the rim edge, preventing potential breakages and achieving proper placement in less time than traditional methods.

Lower Mounting Costs

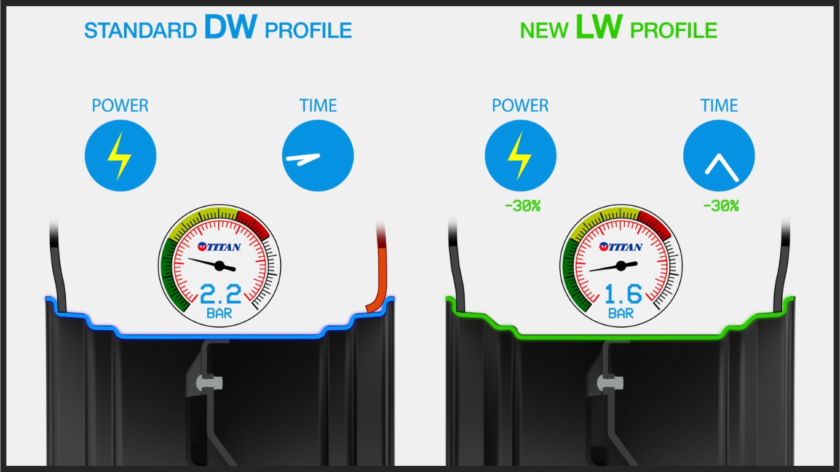

Furthermore, tires can be positioned by inflating them at pressures approximately 30% lower than the industry average, reducing energy consumption during the process and minimizing the risk of blowouts during mounting. The result is more precise, cost-effective installations that are stable and free from bouncing issues.

The new rim is also interchangeable with traditional ones, making it usable not only on tractors but also on large harvesters, thanks to an available range of diameters spanning from 28 to 46 inches.

Title: Titan “Lw”: Stress-Free Mounting

Translation with ChatGPT